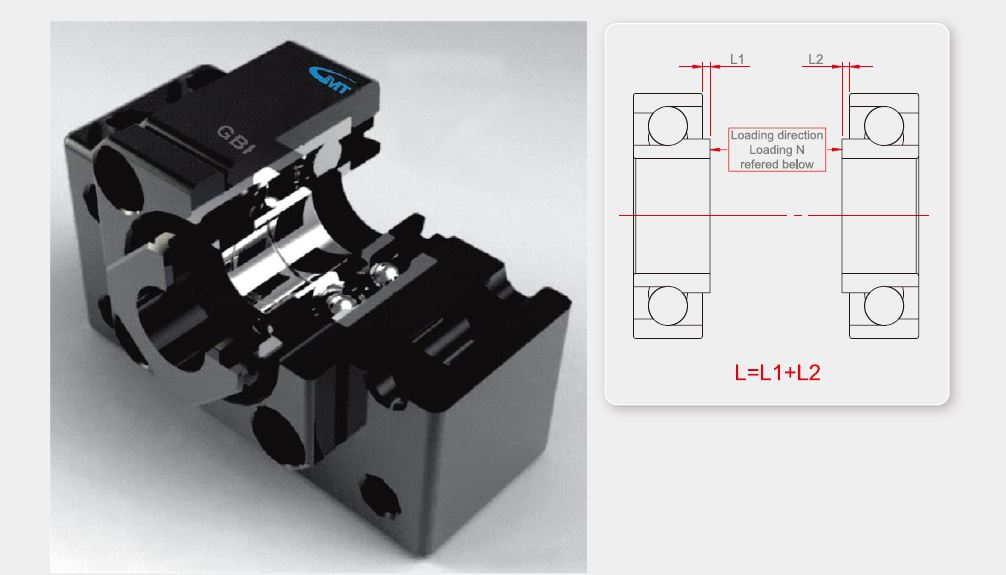

♦ Preload selection and applications - Light (L) * Machine Requirements:Equipments with small vibration and small thrust, load in one fixed direction. High accuracy is not required. Reduction of frictional force. * Application Examples:Laser welder, small CNCmill machine, cutter, welder, automatic tool changer, packing machine, material supply equipment. - Medium (M) * Machine Requirements:Equipments with load on a post. Equipments with a torque acting on it. Equipments working in one direction. Equipments with low load. Equipments with high accuracy. * Application Examples:Automated feeder, linear feeder, automatedpainting machine, precision slide table, Z-axis control on machines, PC board punch machine. Industrial robot, EDM machine, NC lathe. - Heavy (H) * Machine Requirements:High rigidity, high vibration, high thrust equipments. High load, high torque equipments. * Application Examples:Machining center spindle, NC lathe, Z-axis spindle of the machinery, milling machine, grinding wheel feeding of grinding machine. ♦ Pre-Loaded Description - Purpose:1. Increase the rotational accuracy of axle 2. Increase the rigidity of axle 3. Reduce unwanted clearance 4. Reduce vibration and noise while bearing stops. - What is bearing preload?:The preload describes the process wherein a permenant thrust road is applied to the bearing, so that the bearing is secure in the groove and has no axial clearence. Apply normal force (N). Measure value of L of a pair of bearings. L=L1+L2. Press these pair of bearings on the covers to apply preload and bring these bearings together

♦ Selection Notes - [ Model ]:Pick up the model according to assembly method. Assembly: 1. Plane mounting:GAK、GBK、GEK、GAF、GBF、GEF、GSW、GSWE、GUN、GTN。 2. Suspension and spindle mount:GFK、GFF、GRW、GRWE、GUR、GTR。 - [ Size ]:Decide the size according to the ballscrew shaft O.D., and the center height. - [ Grade ]:Standard and economic types for options. - [ Pre-loaded ]:Decide pre-loaded of the bearing per needs. - [ Surface Finish ]: Black dyed - Regular environment use, low humidity. Nickel plating - Clean room use. - [ Bearing category ]:Available Japanese series and Taiwanese series. | -01_6.jpeg)